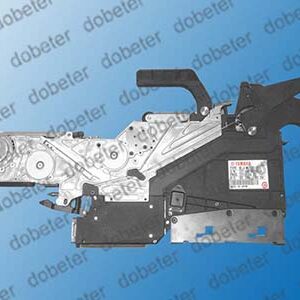

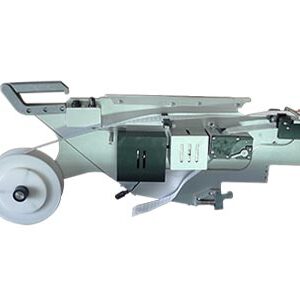

Dobeter provide the KHJ-MD800-00 Yamaha SS/ZS Feeder Tune-Up Station, both used ones and new ones, this tool is a specialized offline unit used to inspect, diagnose, and calibrate older-generation Yamaha SS and ZS series SMT feeders. By performing maintenance away from the production line, it helps ensure that feeders operate accurately and reliably before being installed on a pick-and-place machine.

Key functions of the tune-up station

- Calibration: This is the primary function. Over time, a feeder’s internal mechanism can drift, causing component pickup positions to become inaccurate. The station allows technicians to verify and adjust the component feeding position for various tape widths, such as 8mm, 12mm, 16mm, and 24mm.

- Diagnosis and inspection: It allows technicians to visually and functionally inspect a feeder to identify mechanical and electrical issues. By simulating the machine’s operation, it can detect problems such as faulty stepping motors, worn-out gears, or improper tape indexing.

- Software updates: In some cases, the station allows for the updating of a feeder’s control software to the latest version, which can improve its performance and compatibility.

Importance of regular feeder maintenance

Regular maintenance using a tool like the KHJ-MD800-00 is critical for several reasons:

- Increased uptime: Fewer unexpected feeder failures on the production line mean fewer stops and higher overall equipment effectiveness (OEE).

- Improved placement accuracy: Calibrated feeders are essential for ensuring components are presented at the correct pickup point, which directly impacts the quality of the assembled board.

- Reduced component waste: Mis-picks and feeding errors, which are more common with uncalibrated feeders, lead to wasted components and increased costs.

- Extended feeder lifespan: Regular inspection and timely repair of worn parts can significantly extend the operational life of expensive feeders.