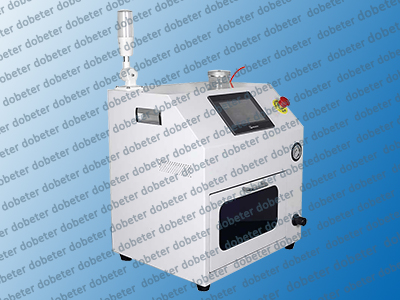

Our SMT Nozzle Cleaner (or SMT nozzle cleaning machine) is an automated system designed to clean, dry, and inspect nozzles used in pick-and-place machines for SMT assembly. The primary goal is to remove solder paste residue, flux, adhesives, dust, and other contaminants from the nozzles, ensuring consistent performance, high placement accuracy, and extended nozzle life.Our SMT Nozzle Cleaner uses high-pressure (and often warm) water, sometimes combined with ultrasonic cleaning, to thoroughly clean nozzles without manual intervention. Some models incorporate PLC and touch screen controls for easy operation and mode selection. By automating the process, the cleaning time per nozzle can be reduced significantly compared to manual cleaning—sometimes to a fraction of the time (e.g., from over 100 seconds down to less than 10 seconds per nozzle for certain processes). Our SMT Nozzle Cleaner In addition to cleaning, Our SMT Nozzle Cleaner also performs drying (often with warm air) and automatic inspection. It checks for proper nozzle conditions (such as tip integrity, air flow, and the absence of blockages) and rejects defective nozzles from the production line. Our SMT Nozzle Cleaner can handle dozens or even hundreds of nozzles in one cycle, making them suitable for high-volume production environments. They often include stocker functions to manage and distribute clean nozzles for subsequent production runs. With the automated process, operator labor and downtime are reduced, contributing to increased overall productivity in SMT lines.

Description for smt nozzle cleaner

video smt nozzle cleaner

Characteristics ::

A : Streamline appearance with elegant design

B : Adopt 20-30 nozzle to do cleaning simultaneously to achieve high efficiency and energy-saving;

B : Inspection windows for the whole process, which makes maintenance and operation more convenient.

C : The part touching with water adopts 304 stainless steel, which is anti-rusted, anti-corrosion, firm and stable;

D : Humanized design which makes external buttons achieve start/stop through one key.

E : Adopt touch screen + PLC distributed control, which makes performance stable and reliable;

F : Easy operation, friendly interface and can be switched between English and Chinese at any moment.

G : It has error-operation alarming system and emergency braking system , equipped with over-loading protecting system; Alarming system and

H : Utilize environment-protecting industrial pure water free from contamination (HPvalue 5-7 soft water);

I : Centralized collection of wastes, which makes maintenance more convenient;

Spare parts in the packing list :