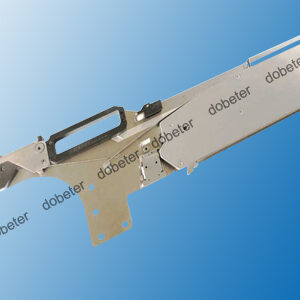

FUJI NXT I Feeder

FUJI NXT I Feeder

Dobeter supply a wide range of FUJI NXT I Feeder, these FUJI NXT I feeders are modular, tape-and-reel feeders used in NXT series surface-mount technology (SMT) pick-and-place machines. As part of a reconfigurable system, these feeders allow electronics manufacturers to adapt to different production needs.

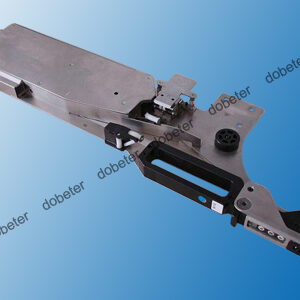

Key features

- Modular design: Feeders can be removed and replaced on NXT machine modules. This enables quick changeovers when switching production lines.

- Tape-and-reel format: NXT I feeders feed components in standard tape and reel formats. They come in various tape widths to accommodate components, from chip resistors and capacitors to larger ICs.

- Horizontal loading: Many NXT feeders have a horizontal loading design, which allows new component reels to be loaded while the machine is running. This minimizes downtime and increases productivity.

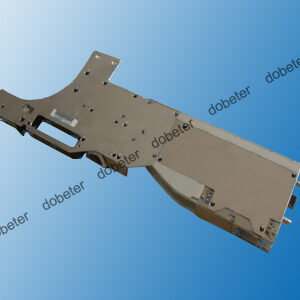

- High compatibility: While designed for the NXT I generation, many feeders are also compatible with later generations, such as the NXT II and NXT III. This provides backward compatibility.

- Intelligent functionality: Some feeders, especially newer ones, have an embedded barcode system to automatically retrieve component information and feeder settings. This helps prevent setup errors and speeds up changeovers.

Common FUJI NXT I feeder sizes

Feeders are identified by a part number that often includes the tape width (e.g., W08, W12) and may specify the generation (e.g., KT8BC). Common sizes include:

- 8mm feeder: For small chip components.

- 12mm feeder: For slightly larger chips and some small ICs.

- 16mm feeder: For medium-sized components.

- 24mm feeder: For larger components.

- 44mm and 56mm feeders: For bigger and specialty parts.

Feeder maintenance and performance

Proper maintenance is important for feeder performance and component placement accuracy. Common issues that can arise from poor maintenance include:

- Inaccurate component pickup location, which can lead to parts shifting or falling off the nozzle.

- Poor feeding of the component tape, resulting in machine stops.

Regular cleaning, lubrication, and calibration of the feeders are necessary to maximize uptime and extend their service life. Many suppliers also offer spare parts, such as feeder gears and stepping motors, for maintenance and repairs.

Showing all 16 results

-

FUJI Feeders

FUJI NXT Feeder 12MM W12 AA84128

-

FUJI Feeders

FUJI NXT Feeder 16MM W16 AA84228

-

FUJI Feeders

FUJI NXT Feeder 24MM W24 AA84328

-

FUJI Feeders

FUJI NXT Feeder 32MM W32 AA84426

-

FUJI Feeders

FUJI NXT Feeder 44MM W44 AA84525

-

FUJI Feeders

FUJI NXT Feeder 56MM W56 AA84625

-

FUJI Feeders

FUJI NXT Feeder 72MM W72 AA2GZ03

-

FUJI Feeders

FUJI NXT Feeder 88MM W88 AA2HA03

-

FUJI Feeders

FUJI NXT Feeder 8MM W08 AA84030

-

FUJI Feeders

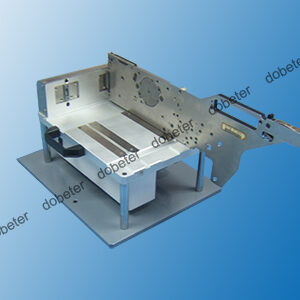

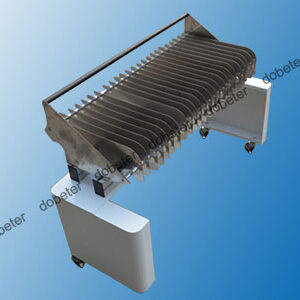

FUJI NXT Feeder Cart

-

FUJI Feeders

FUJI NXT Feeder Loading Unit

-

FUJI Feeders

FUJI NXT Feeder rack

-

FUJI Feeders

FUJI NXT Feeder W72, With Reel Holder UF02500

-

FUJI Feeders

FUJI NXT Feeder W88, With Reel Holder UF02600

-

FUJI Feeders

FUJI XPF component reel cart