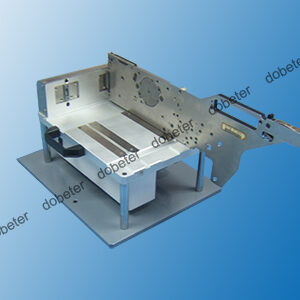

FUJI NXT III Feeder

FUJI NXT III Feeder

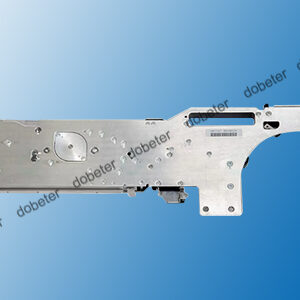

Dobeter supply a wide range of FUJI NXT III feeders, these FUJI NXT III Feeder are the third generation of Fuji’s modular feeder system, designed to work with NXT III and NXT IIIc surface-mount technology (SMT) pick-and-place machines. These feeders continue the tradition of modularity and intelligence, with enhancements aimed at improving speed, accuracy, and ease of use.

Key features

- Intelligent “F” series feeders: The

NXT III

uses the “F” series of intelligent feeders, such as the W08F and

W16F

. These feeders are equipped with advanced functions for identifying components, which helps eliminate setup errors, reduce downtime, and improve overall production quality.

- Wider component support: The NXT III feeder system can handle a broad range of component sizes, from the smallest 03015 chips to larger, odd-form parts up to 38.1 mm in height.

- High compatibility: A key design goal for the NXT III was ensuring compatibility with previous generations. Many NXT II main units, including heads, tray units, and feeder pallets, are compatible with the NXT III, allowing manufacturers to leverage existing investments.

- Hot-swappable pallets: Feeders are arranged on modular pallets, which can be exchanged without stopping the machine. This functionality allows for offline setup and rapid product changeovers, maximizing machine uptime and productivity.

- Enhanced speed and accuracy: The NXT III machine is designed for higher throughput, and its feeders are optimized for faster performance. A rigid machine structure and advanced servo control improve placement accuracy to ±0.025 mm (Cpk ≥ 1.00).

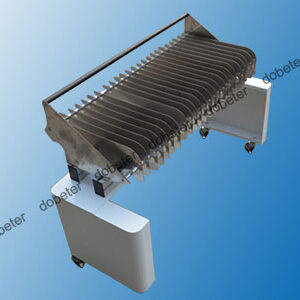

- Advanced maintenance tools: Fuji offers an optional Auto Feeder Maintenance Unit for the NXT III. This unit automates the cleaning, lubrication, and inspection of feeders, helping to maintain high component supply stability and placement accuracy over time.

Common

NXT III

feeder types

- Tape feeders: The primary feeders for the NXT III are tape-and-reel feeders, available in a variety of standard widths, including 4, 8, 12, 16, 24, 32, 44, 56, 72, 88, and 104 mm. Common intelligent F-series tape feeders include the

W04F, W08F, W12F, and W16F

.

- Stick feeders: These are designed for supplying parts that come in stick or tube packaging.

- Tray units: The NXT III supports several tray unit options for components supplied in JEDEC standard trays.

NXT III feeder maintenance and performance

Consistent performance from NXT III feeders requires regular maintenance. The intelligent design and dedicated inspection and maintenance units help reduce feeder-related production stops. Key maintenance practices include:

- Using the Intelligent Feeder Inspection station to check and adjust feeder condition.

- Automated cleaning, lubrication, and adjustment of tape indexing with the Auto Feeder Maintenance Unit.

- Managing maintenance records for individual feeders to track and ensure stable performance.

Showing all 23 results

-

FUJI Feeders

FUJI NXT Feeder Cart

-

FUJI Feeders

FUJI NXT Feeder Loading Unit

-

FUJI Feeders

FUJI NXT Feeder W72, With Reel Holder UF02500

-

FUJI Feeders

FUJI NXT Feeder W88, With Reel Holder UF02600

-

FUJI Feeders

FUJI XPF component reel cart