Hanwha Feeder Cart

Hanwha Feeder Cart

Dobeter provide a wide range of Hanwha feeder cart, which is a mobile storage and kitting solution used in SMT assembly to manage and transport feeders. These carts are compatible with Hanwha (formerly Samsung) SM-series, CP-series, and Decan pick-and-place machine feeders. By allowing feeders to be prepared offline, feeder carts significantly reduce changeover time and increase overall production efficiency.

Key functions of Dobeter’s Hanwha feeder cart

- Offline kitting: An operator can “pre-kit” a cart with all the necessary feeders for an upcoming production run. This allows the pick-and-place machine to continue running the current job without interruption.

- Feeder storage: Feeder carts provide a secure and organized place to store unused feeders, protecting them from damage or loss.

- Transportation: The wheeled design allows a cart to be easily moved to the pick-and-place machine when a changeover is needed. After a job is complete, the feeders can be quickly swapped and the old feeders moved away for restocking.

Design and features of Dobeter’s Hanwha feeder cart

- Material: Hanwha feeder carts are typically constructed from a durable, lightweight, and non-magnetic material like aluminum alloy or stainless steel.

- Storage capacity: The carts are designed with multiple levels and slots to hold dozens of feeders. A common capacity is between 50 and 80 feeders, depending on the model.

- Antistatic protection: To prevent damage to sensitive electronic components, the carts often include a grounding chain or are designed with static-dissipative materials.

- Braking casters: The wheels are equipped with brakes to secure the cart in place during kitting and changeover.

- Compatibility: Different carts are manufactured to accommodate specific Hanwha/Samsung feeder types, including the newer SME electric feeders and older SM and CP pneumatic feeders.

Benefits in SMT manufacturing of Dobeter’s Hanwha feeder cart

- Reduced changeover time: Offline preparation of component kits using a feeder cart dramatically cuts down the time the pick-and-place machine spends idle between jobs.

- Improved organization: With a designated space for every feeder, the carts help streamline material management and prevent mix-ups.

- Minimized errors: The kitting process can be performed in a more controlled environment, reducing the chance of human error during feeder loading and placement.

- Enhanced safety: Securely storing feeders on a cart prevents accidental damage and reduces the risk of dropped or spilled components.

Showing all 6 results

-

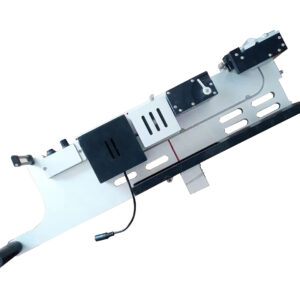

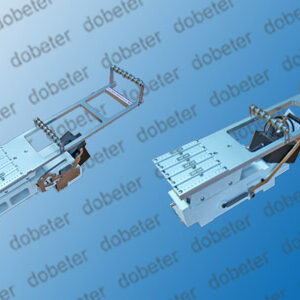

Hanwha Feeder Cart

Hanwha feeder cart

-

Hanwha Feeder Cart

Hanwha feeder cart

-

Hanwha CP Feeder

Hanwha Label Feeder

-

Hanwha Electric Feeder

Hanwha stick feeder

-

Hanwha Electric Feeder

Hanwha stick feeder

-

Hanwha Electric Feeder

Hanwha vibration feeder