Hanwha SME Feeder

If you’re using a Hanwha‑branded (Samsung legacy) SMT pick‑and‑place machine, an Hanwha SME feeder is the electrically driven, “smart” version of the older pneumatic SMN feeders. Here’s everything you need to know:

What Is an SME Feeder?

SMN = Pneumatic feeder requiring mechanical reels and often manual pitch setup.

SME = Electric SMART feeder with built‑in motors for precise tape advance, pitch auto-recognition, and automatic cut/strip functions.

Compared with SMN:

Higher throughput & fewer jams, Automatic setup & diagnostics, Faster calibration, Less maintenance overhead

Available Sizes & Component Fit for Hanwha SME feeder :

| Feeder Model | Tape Width | Typical Component Range (mm) | Recommended Hanwha Machines |

| —————- | ——————— | —————————————————— | ——————————- |

| SME 8mm | 8 mm (incl. 8×2, 8×4) | 0402, 0603, small passives | SM320/SM421/SM471/SM481 |

| SME 12mm | 12 mm | Small chips, LEDs, connectors | SM421 / SM471 / SM482 |

| SME 16mm | 16 mm | Medium chips & ICs (1005–1608) | SM421 / SM471 / SM482 |

| SME 24mm | 24 mm | Large resistors, SOT ICs | SM471 / SM481 / SM482 |

| SME 32mm | 32 mm | HD chip caps, SC‑70 / SOP8 | SM481 / SM482 |

| SME 44mm | 44 mm | 0.5″–1″ ICs, test connectors | SM481 / SM482 |

| SME 56mm | 56 mm | Large DIPs, flat packages | SM481 / SM482 |

| SME 72mm | 72 mm | Extra‑large components (e.g., heat sinks, large coils) | SM482 only |

Why Choose for Hanwha SME feeder Over Hanwha SMN feeder

1. Plug‑and‑run setup: no manual pitch or cut setup—feeders automatically detect tape format.

2. Consistent precision: electric motors reduce mis-feeds and component drop chances.

3. Built‑in diagnostics: auto‑error detection and reset reduce downtime.

4. Lower parts wear & calibration: no air cylinders; digital controls.

5. Higher feeder speed: supports ultra-fast cycle rates.

Troubleshooting & Maintenance

Hanwha SME feeder Calibration jig: A dedicated fixture (often sold under the same smart feeder brand) helps realign sensors when accuracy degrades.

Hanwha SME feeder : Clean feed wheels and tape sensors regularly to maintain ESD compliance and pitch detection.

Hanwha SME feeder : Summary

Choosing the correct SME feeder model depends on your:

Feeder port pitch orientation (2mm vs. 4mm)

Component size (tape width & pitch)

Machine model (SM310 / SM421 / SM481 / SM482 / Decan / Excen etc.)

Showing all 13 results

-

Hanwha Electric Feeder

Hanwha Label Feeder

-

Hanwha CP Feeder

Hanwha Label Feeder

-

Hanwha Feeders

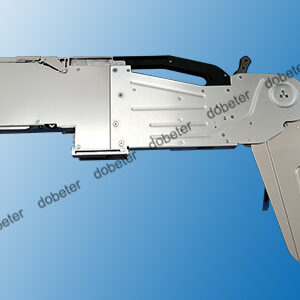

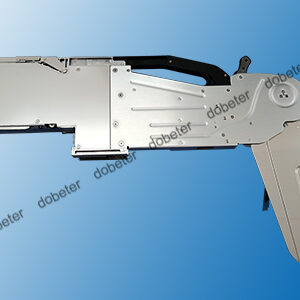

Hanwha SME feeder 12mm

-

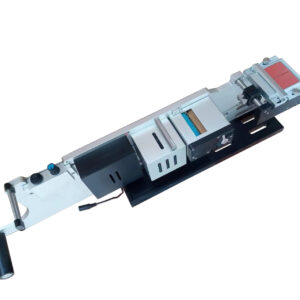

Hanwha Feeders

Hanwha SME feeder 16mm

-

Hanwha Feeders

Hanwha SME feeder 24mm

-

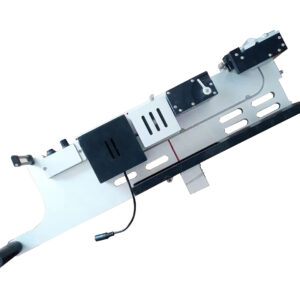

Hanwha Feeders

Hanwha SME feeder 32mm

-

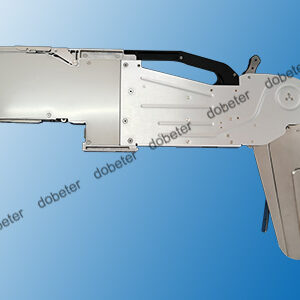

Hanwha Feeders

Hanwha SME feeder 44mm

-

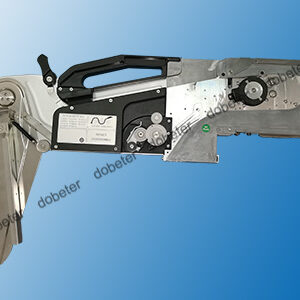

Hanwha Feeders

Hanwha SME feeder 56mm

-

Hanwha Feeders

Hanwha SME feeder 8mm pi 08m with large reel holder

-

Hanwha Feeders

Hanwha SME feeder 8mm pi 08s

-

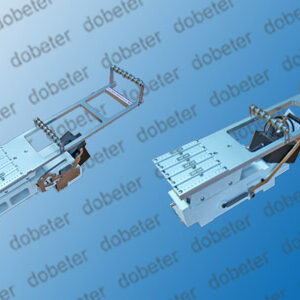

Hanwha Electric Feeder

Hanwha stick feeder

-

Hanwha Electric Feeder

Hanwha stick feeder

-

Hanwha Electric Feeder

Hanwha vibration feeder