Panasonic NPM Feeders

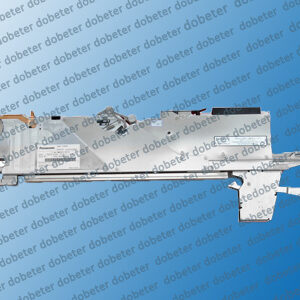

Dobeter provide a wide range of Panasonic NPM feeders, which are essential automated component supply devices for SMT pick-and-place machines, designed to enhance precision, speed, and efficiency in electronic assemblies, and come in various sizes and configurations to suit diverse production needs in 2025.

Panasonic NPM feeders are integral to Surface Mount Technology (SMT) production, feeding electronic components from tape, tray, or stick formats into Panasonic NPM series pick-and-place machines. These Panasonic NPM feeders ensure accurate and reliable supply of components such as resistors, capacitors, ICs, and connectors, enabling precise placement on Printed Circuit Boards (PCBs). Panasonic NPM feeders vary by tape width and type, including 8mm, 12/16mm, 24/32mm, 44/56mm, 72mm, and 88mm sizes, accommodating different component dimensions and packaging formats.

Types and Models of Panasonic NPM Feeders

– 8mm Tape Feeders: Widely used for small components, Panasonic offers models such as N610003478AA (single feeder with sensor) and KXFW1KS5A00 (double feeder with sensor) designed for high precision and compatibility with NPM, CM602, and CM402 machines .

– 12/16mm Feeders: Suitable for medium-sized components, models such as KXFW1KSCA00 and KXFW1KSDA00 provide versatility and are made for high-speed SMT production lines.

– Larger Feeders (24mm and above): Models including KXFW1KSFA00 cater to larger or bulkier components, enhancing productivity by minimizing feed errors and downtime .

– Specialized Feeders: Panasonic also offers feeders designed for handling atypical or large components and high-speed heads compatible with their latest machines like NPM-GW, which support automated supply and reduced setup times via Auto Setting Feeders (ASF) and Automatic Process Control (APC-5M) systems .

Key Features and Benefits of Panasonic NPM feeders

– Compatibility: Panasonic feeders seamlessly integrate with NPM and related series SMT machines, ensuring smooth operation and minimal setup time .

– High Precision and Speed: These feeders are designed for exact tape feeding, minimizing misfeeds and jams that can halt production. Some support intelligent control systems that adapt feeding speed dynamically .

– Automation and Efficiency: Auto Setting Feeders enable automatic material supply, reducing manual labor and production downtime while enabling quick reel changes without interruptions.

– Flexibility: Across tape sizes and feeder types, Panasonic offers a range of feeders ideal for handling from tiny 0201 components up to large connectors or heavy chips, meeting diverse assembly demands .

– Maintenance and Durability: With regular maintenance—such as cleaning and calibration—and robust design, Panasonic feeders deliver long-term stable performance. Support and replacement parts are widely available .

How to Choose the Right Panasonic NPM feeders

– Component Size: Select feeders matching the tape width and component size to avoid feeding errors. For small components, 8mm feeders are common; larger parts need wider tape feeders .

– Machine Compatibility: Evaluate compatibility with your specific NPM model (e.g., NPM-D3, NPM-WX) and confirm feed system integration .

– Production Speed and Accuracy Needs: Consider feeder speed capabilities and error tolerance; AI-enhanced and smart feeders help maintain precision at high throughput .

– Type of Components: For bulk components or atypical parts, specialized feeders are available to maintain placement precision and reduce downtime.

Maintenance and Support

– Routine cleaning and alignment checks prevent jams and misfeeds.

– Proper storage in feeder carts maintains physical integrity and eases handling .

– Panasonic provides comprehensive technical support and after-sales service, including troubleshooting, spare parts availability, and training for feeder setup and calibration, maximizing uptime and production efficiency .

Showing all 30 results

-

Panasonic Feeders

Panasonic Feeder 104MM Feeder With Sensor KXFW1L11A00

-

Panasonic Feeders

Panasonic Feeder 12/16mm Feeder With Sensor KXFW1KS6A00

-

Panasonic Feeders

Panasonic Feeder 12/16mm Feeder Without Sensor KXFW1KSCA00

-

Panasonic Feeders

Panasonic Feeder 24/32mm Feeder With Sensor KXFW1KS7A00

-

Panasonic Feeders

Panasonic Feeder 24/32mm Feeder With Sensor KXFW1L10A00

-

Panasonic Feeders

Panasonic Feeder 24/32mm Feeder With Sensor N610004577AA

-

Panasonic Feeders

Panasonic Feeder 24/32mm Feeder Without Sensor KXFW1KSRA00

-

Panasonic Feeders

Panasonic Feeder 24/32MM Without Sensor KXFW1KSDA00

-

Panasonic Feeders

Panasonic Feeder 44/56mm EMBOSS Feeder Depth 21mm KXFW1L0YA00

-

Panasonic Feeders

Panasonic Feeder 44/56mm Feeder With Sensor KXFW1KS8A00

-

Panasonic Feeders

Panasonic Feeder 44/56mm Feeder With Sensor EMBOSS depth21mm KXFW1L0TA00

-

Panasonic Feeders

Panasonic Feeder 44/56mm Feeder With Sensor EMBOSS depth21mm KXFW1L0UA00

-

Panasonic Feeders

Panasonic Feeder 44/56mm Feeder Without Sensor KXFW1KSEA00

-

Panasonic Feeders

Panasonic Feeder 72MM EMBOSS Feeder With Sensor KXFW1L0ZA00

-

Panasonic Feeders

Panasonic Feeder 72MM Feeder With Sensor KXFW1KS9A00

-

Panasonic Feeders

Panasonic Feeder 72MM Feeder With Sensor KXFW1KSGA00

-

Panasonic Feeders

Panasonic Feeder 72MM Feeder Without Sensor KXFW1KSFA00

-

Panasonic Feeders

Panasonic Feeder 8MM DOUBLE Feeder With Sensor KXFW1KS5A00

-

Panasonic Feeders

Panasonic Feeder 8MM DOUBLE Feeder Without Sensor KXFW1KSBA00

-

Panasonic Feeders

Panasonic Feeder 8MM SINGLE With Sensor N610003476AA

-

Panasonic Feeders

Panasonic NPM 8mm Double feeder N610031082AA

-

Panasonic Feeders

Panasonic NPM 8mm Single Feeder N610003478AA

-

Panasonic Feeders

Panasonic NPM Feeder Calibration Jig

-

Panasonic Feeders

Panasonic NPM Feeder Cart 1

-

Panasonic Feeders

Panasonic NPM Feeder Cart 2

-

Panasonic Feeders

Panasonic NPM Feeder Cart 3

-

Panasonic Feeders

Panasonic NPM Feeder Cart 4

-

Panasonic Feeders

Panasonic NPM Stick Feeder

-

Panasonic Feeders

Panasonic NPM Vibration Feeder