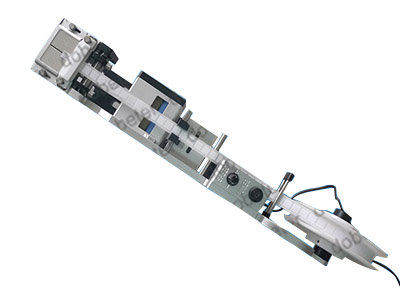

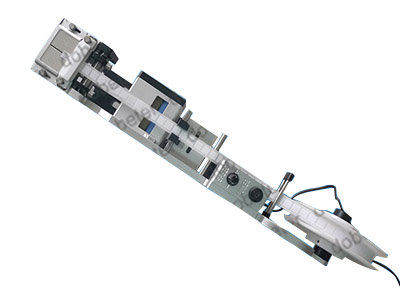

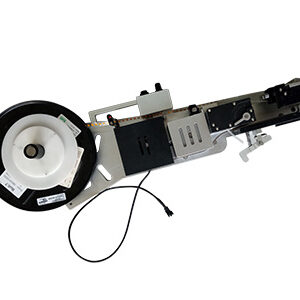

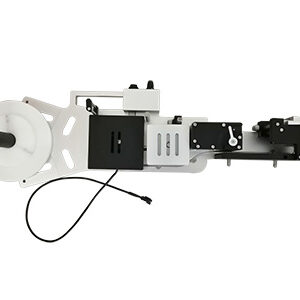

Fuji Label Feeder

Applied to : those Fuji SMT machines such as XP141,XP142, XP143, CP8,IP, IP2,IP3,QP132, QP242,QP341 and so on.

Fuji label feeder into Fuji SMT machine:

We have three Liner(web) width for Fuji label feeder, 50mm, 85mm and 100mm, also we can make customized Liner Width as your request, so our label feeder can peel and present more than 2 lables at one time, so it is more efficient and productive.

Specs :

| Specification | Minimum | Maximum |

| Media Size | 2 mm x 2 mm | 31 mm to customized one * 50 mm,

31 mm to customized one * 85mm , 31 mm to customized one * 100mm |

| Media Thickness | 0.05 | 1 |

| Liner Width | 1 | 50mm

85mm 100mm customized one |

| Liner Thickness | 0.05 | 1 |

| Feed Rate | 0 mm / sec | 95 mm / sec |

We also supply you Cutomized nozzle for Fuji label feeder , send us your datasheet for labels or samples we can design and manufacture the special nozzles for you .

Dobeter manufacture Fuji Label Feeder, this Fuji Label Feeder enables seamless, high-speed automatic placement of labels on PCBs using existing Fuji SMT pick-and-place machines, improving accuracy and productivity while reducing manual labor and cost. Dobeter’s Fuji Label Feeder is an accessory compatible with Fuji SMT pick-and-place machines such as XP141, XP142, XP143, CP8, IP series, QP132, QP242, QP341, and more. It feeds adhesive-backed labels or other strip labels to the pick-and-place system, allowing the machine to handle labels as if they were standard electronic components. This eliminates the need for separate labeling machines or manual label placement, saving floor space and reducing labor costs. This Fuji Label Feeder is compatible and ease of use: Simply add a vision file for the label as if it were a leadless chip component—no special programming or training needed. It works with many Fuji SMT machine models , also it supports a variety of adhesive media, including paper labels, plastic, foam, thermal pads, Kapton dots, shields, metal sheets, and more, feeding single or multiple labels simultaneously for higher efficiency .

– Technical Specifications:

– Media Size: From 2mm x 2mm to customized widths up to 100mm or more.

– Thickness Compatibility: 0.05 to 1.0 mm.

– Feed Rate: Up to 95 mm/sec or higher depending on specific models.

– Feeding Accuracy: ±0.1 mm positioning accuracy ensures precise label placement .

– Customization: Specialized nozzles can be designed to handle unique label materials and sizes, further enhancing flexibility .

– Improved Productivity: Automating label placement at normal machine rates boosts throughput and accuracy compared to manual methods. It also reduces maintenance costs and minimizes errors from hand placement or standalone labeling systems .

How It Works

The label feeder automatically peels the label from the liner and presents it for pickup by the SMT placement nozzle. The feeder uses fiber optic sensors or other precise feedback mechanisms to detect label position, calibrate placement, and adjust feeding dynamically, preventing errors during production runs .

Advantages Over Alternatives

– Does not require purchasing expensive separate label applicators or occupying additional factory space.

– More cost-efficient and faster than hand placement.

– Handles various label types and sizes with simple parameter settings on existing Fuji machines.

– Can be integrated easily without complex programming or changes in the SMT line .

Common Applications

Used to place barcode labels, thermal pads, distance pads, protective masks, metal sheets, and other adhesive-backed components, the Fuji Label Feeder is versatile for electronics manufacturing where efficient marking, part protection, or component identification is needed .

In summary, the Fuji Label Feeder offers a robust, flexible, and cost-effective solution to automating label placement on PCBs within Fuji SMT pick-and-place operations, helping improve line efficiency, accuracy, and reduce costs without the need for dedicated labeling equipment.