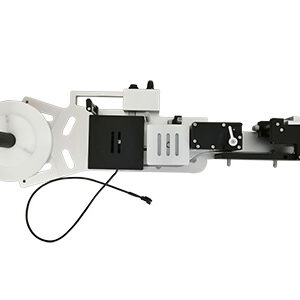

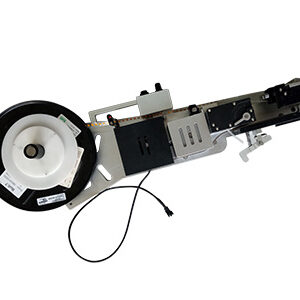

When calibrating Hanwha (formerly Samsung) SMT feeders—whether SM (pneumatic) or SME (electric smart) types—the Hanwha Feeder Calibration Jig (also known as DBE‑FCJ‑SAM‑SM‑TRD / SAM‑NEW) is the dedicated tool used to verify and adjust feeder alignment, pin ejection, tape feed positioning, and accuracy across multiple tape widths (8mm up to 24mm)

Typical Workflow for Hanwha Feeder Calibration Jig:

1. Mount feeder onto jig.

2. Run automated or manual feed test, simulating actual SMT machine operation.

3. Use on-screen crosshair and magnified image to ensure pocket center and eject pin align within spec.

4. Verify repeatability: typically performing 30–60 feed cycles and confirming the pocket remains within tolerance—if not, calibration or service is needed ([Alibaba][4], [SMTBOX INC.][5]).

For Hanwha Feeder Calibration Jig, detailed service and spare parts listings are available—covering optical components, XYZ stage assembly, base boards, cables, and master toggles

For Hanwha/Samsung SM or SME feeders, the Samsung Feeder Calibration Jig (DBE‑FCJ series) is the standard tool for alignment, feed accuracy, and diagnostics.

Compatible with CP, SM, SME feeders across models like SM320/421/481/482 and CP40/45, etc.

Includes precision CCD, multiple axis adjustment, simulation modes, and line generator display for visual feedback.

Spare parts and calibration accessories are available under specific assembly part numbers.