Panasonic Custom Nozzles

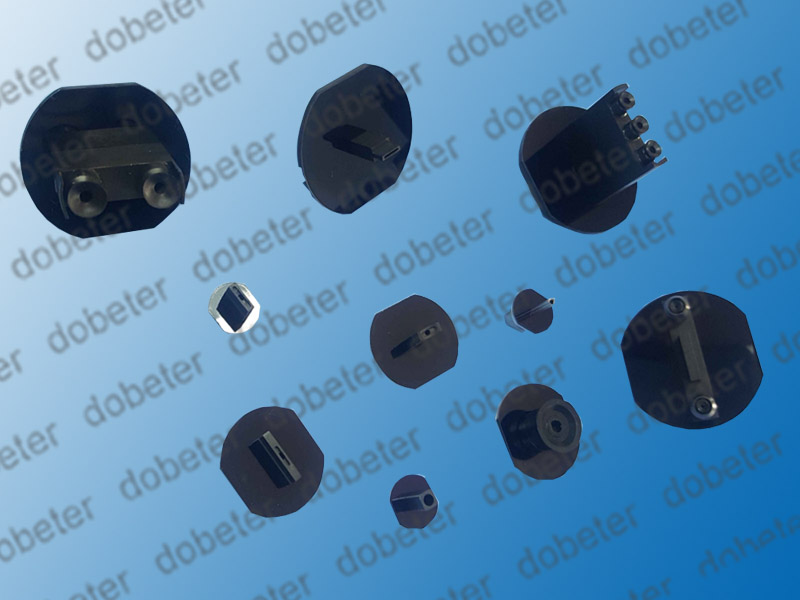

Dobeter offers Panasonic custom nozzles for its pick-and-place equipment to handle a variety of non-standard and odd-form components.

Panasonic Custom nozzles for Panasonic SMT machines are tailored to accommodate a wide range of component shapes, sizes, and materials.

Panasonic Gripper nozzles: These use mechanical jaws instead of vacuum suction to hold onto a component. They are especially useful for irregularly shaped parts or components that are too heavy for a standard vacuum nozzle to pick up reliably.

Dobeter supply a variety of Panasonic Custom Nozzles :

V-groove nozzles: Ideal for components with an unusual or jagged shape, these nozzles provide a more secure fit than a standard nozzle, preventing slippage during placement.

Specialized tips: Panasonic Custom nozzles can be equipped with various tips to meet unique component requirements.

Urethane tips for handling delicate components like certain LED series.

Ceramic tips for improved durability and performance with specific components.

PTFE tips for components that require special handling, such as those sensitive to electrostatic discharge (ESD).

O-nozzles: These are highly specialized nozzles with a precise diameter for picking and placing very small, challenging components like miniature resistors and capacitors.

Dobeter ‘s Panasonic Custom nozzles are available for a wide range of Panasonic SMT machine models, including both older and newer series :

NPM series: Many custom nozzles are available for the NPM series, which includes multi-functional machines like the NPM-W2 and NPM-DX.

CM series: Older machine series, such as the CM402 and CM602, are also compatible with various custom nozzles.

NPM-VF: For the most complex odd-form parts, Panasonic offers specialized odd-form component insertion machines like the NPM-VF, which uses advanced robotics and custom tooling to handle challenging

Component sample analysis: Customers provide a sample or drawing of the component they need to place.

Engineering and design: Specialized engineers design a nozzle that provides a secure grip, reliable vacuum pressure (if applicable), and compatibility with the machine’s placement head.

Manufacturing and testing: The nozzle is then manufactured from the appropriate material and tested to ensure it meets quality and performance standards.