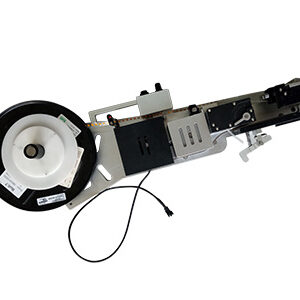

Samsung Label Feeder

Part number: DBE-LF-SS-SM

Applied to : CP60, CP50, CP45,CP40,SM451, SM421, SM411, SM320, CP45Neo and so on.

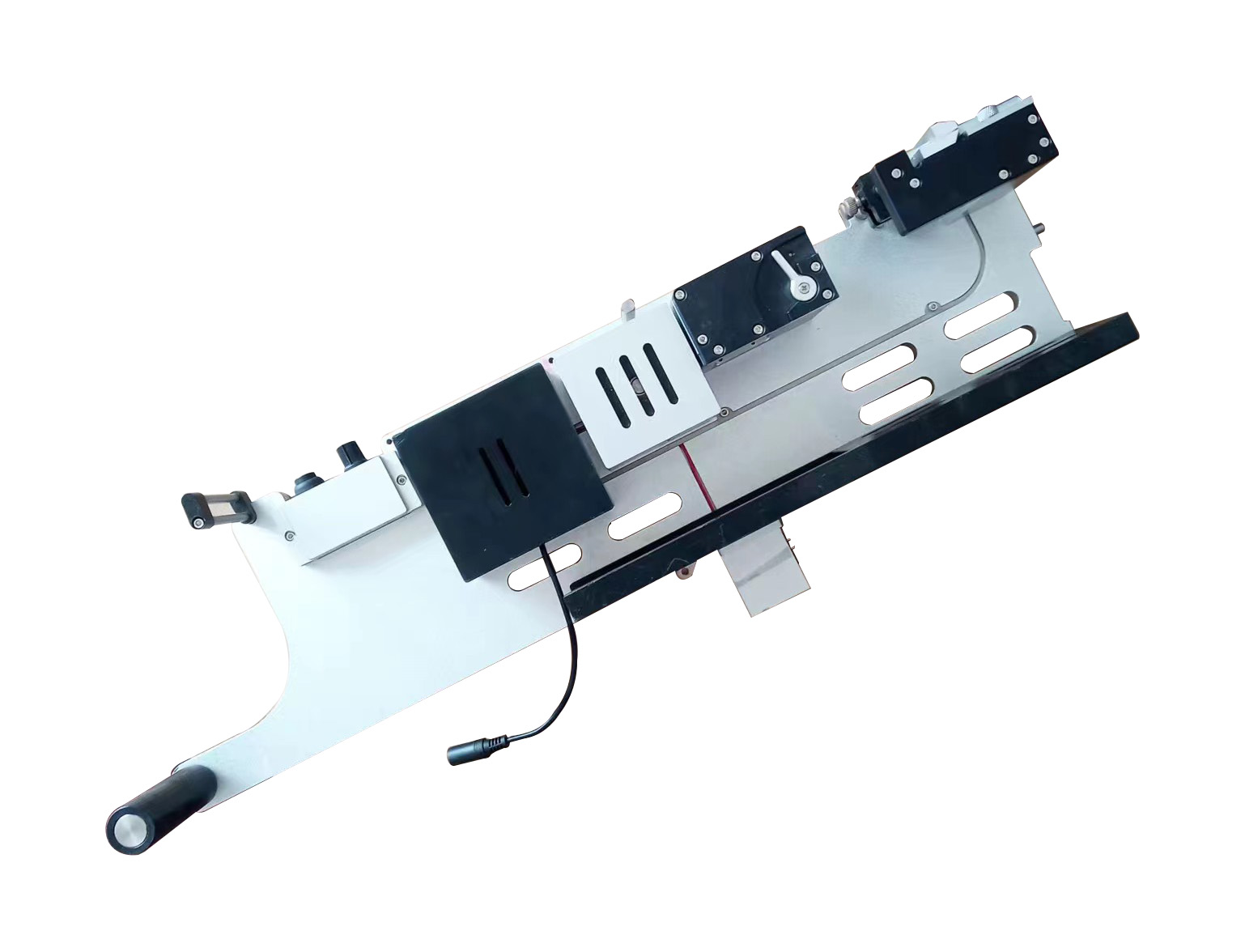

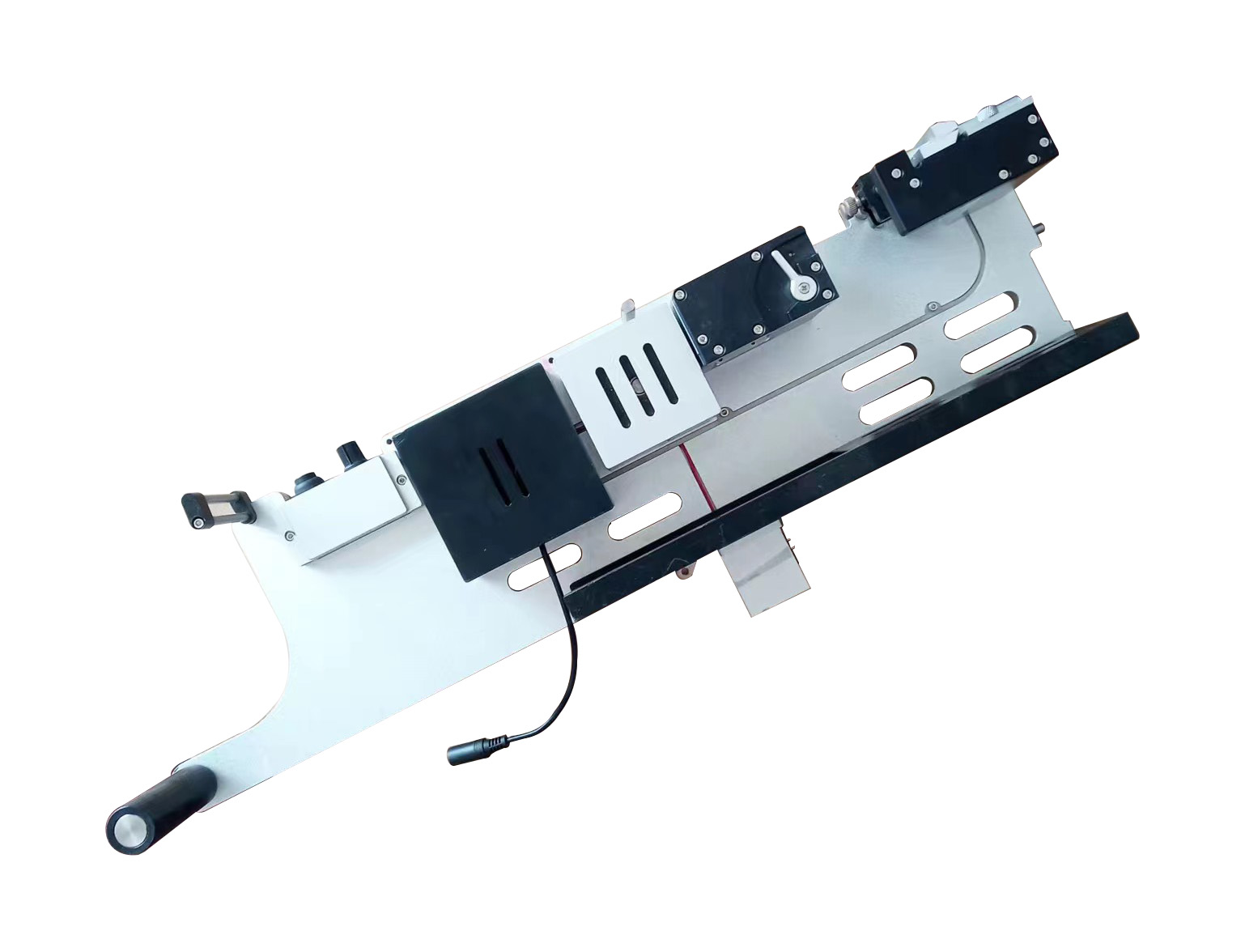

Samsung label feeder into Samsung SMT machine:

Samsung Label Feeder 2

Part number: DBE-LF-SS-CP

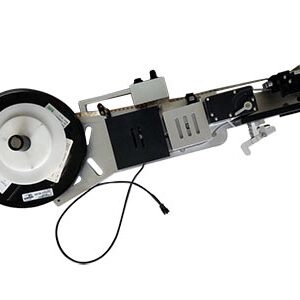

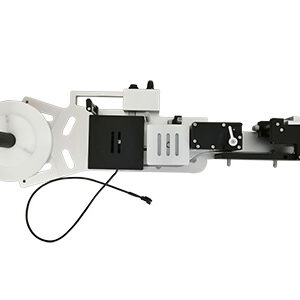

Applied to : CP45,CP40,CP20 and so on.

Samsung label feeder into Samsung SMT CP45,CP40,CP20 machine:

We have three Liner(web) width for Samsung label feeder, 50mm, 85mm and 100mm, also we can make customized Liner Width as your request, so our label feeder can peel and present more than 2 lables at one time, so it is more efficient and productive.

Specs :

| Specification | Minimum | Maximum |

| Media Size | 2 mm x 2 mm | 31 mm to customized one * 50 mm,

31 mm to customized one * 85mm , 31 mm to customized one * 100mm |

| Media Thickness | 0.05 | 1 |

| Liner Width | 1 | 50mm

85mm 100mm customized one |

| Liner Thickness | 0.05 | 1 |

| Feed Rate | 0 mm / sec | 95 mm / sec |

We also supply you Cutomized nozzle for Samsung label feeder , send us your datasheet for labels or samples we can design and manufacture the special nozzles for you :

Dobeter manufacture Samsung Label Feeder, this Samsung Label Feeder is an automatic feeder designed for Samsung SMT pick-and-place machines to efficiently and accurately present and place labels and adhesive-backed materials onto PCBs, improving speed and precision while reducing manual labor. Dobeter’s Samsung Label Feeder is a specialized SMT (Surface Mount Technology) feeder used on Samsung/Hanwha pick-and-place machines to automatically dispense labels. This process provides high-speed, precise, and traceable labeling for printed circuit boards (PCBs) and other electronic assemblies. The Samsung Label Feeder integrates seamlessly with existing Samsung SMT placement machines such as CP60, CP50, CP45, CP40, SM451, SM421, SM411, SM320, CP45Neo, and CP20 series. It allows the machines to pick and place various labels including barcode labels, thermal pads, shields, Kapton dots, metal sheets, and other adhesive-backed parts as if they were regular components. This eliminates the need for separate labeling machines, saving floor space and cutting equipment costs while streamlining production .

- Enhanced traceability: The use of barcoded or QR-coded labels enables manufacturers to track individual products throughout the entire assembly process. This is crucial for quality control, root cause analysis, and product recalls.

- Improved accuracy: Label feeders eliminate human error associated with manual labeling, ensuring labels are placed with a high degree of precision in a repeatable manner.

- Increased efficiency: The process is automated, significantly speeding up production compared to manual placement.

- Cost reduction: By automating a manual task, manufacturers can reduce labor costs and avoid the costs associated with incorrect label placement.

- Versatility: These feeders can handle different sizes and types of adhesive materials, not just labels. This includes protective films, foam pads, and conductive adhesives.